Fig. 12. If Pressure is Below Normal

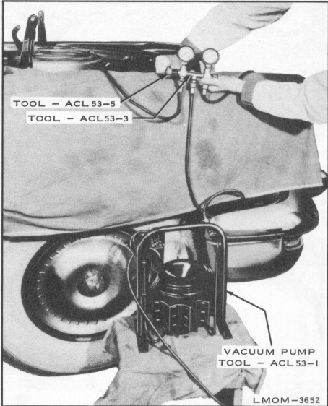

Fig. 13. Connect Pump and Evacuate

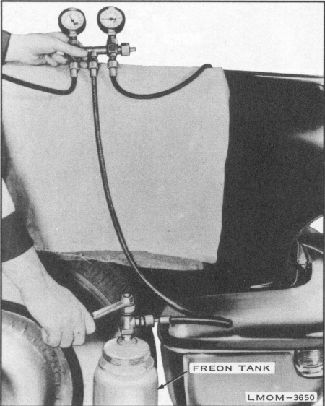

Attach Freon Tank - Open Tank Valve

System to Approximately 27"

Tool - ACL53-3, counterclockwise and slowly

release system pressure through manifold

center hose.

8. When both high and low pressure gauges

of the

Pressure Test Gauge Manifold read "O"

P.S.I.

attach manifold center hose to Vacuum

Pump, Tool

- ACL53-1 and evacuate until system reaches

27"

of mercury. See figure 13. CAUTION: Do

not

connect center hose of the Pressure Test

Gauge

Manifold to Vacuum Pump when there is

still

pressure in system.

9. Turn low pressure gauge valve of the

Pressure

Test Gauge Manifold, Tool - ACL53-3

clockwise until fully closed, then disconnect

vacuum pump.

10.

Invert Fr eon tank on a scale and attach

center

hose of the Pressure Test Gauge Manifold

to

Freon tank. (Scale will measure amount

of

Freon going into system. Fully charged

system

has approximately 7 lbs.)

11. Open Freon tank valve.

12. By intermittently opening and closing

low

pressure valve of the Pres-sure Test Gauge

Manifold, Tool

- ACL53-3, (approximately 1/4 turn) allow

liquid Freon to be drawn into system until

pressure reaches 45 P.S.I. See figure

14.

13. Close low pressure valve of the Pressure

Test

Gauge Manifold, Tool - ACL53-3, start

engine and run at 1500 R.P.M.