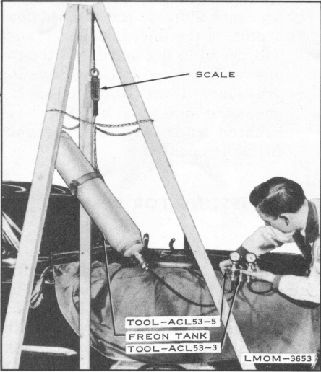

Fig. 14. Bring Pressure to 45 P.S.I.

With engine running at 1500 R.P.M.

intermittently open and close low pressure

valve of the Pressure Test Gauge Manifold

(approximately 1/4 turn), and allow liquid

Freon to flow into system. CAUTION: Gauge

manifold will get cold, however, excessive

frosting indicates too fast a flow.

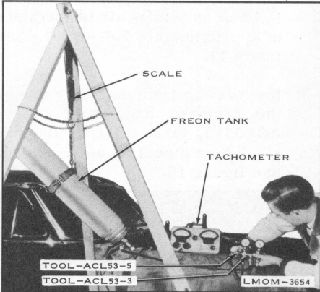

When system is fully charged, there will be no

bubbles visible in sight gauge, the high pressure

gauge will read between 90 and 120 P.S.I., the

low pressure gauge will read between 15 and

25 P.S.I. and there will be approximately 7 lbs.

of Freon in the system. See figure 15.

Turn high pressure valve, located on condenser

and low pressure valve, located on right front

fender apron, counterclockwise to the fully

opened position, using Tool - ACL53-5.

Fig. 15. Charge the System

17.

Turn off Fr eon tank valve.

18. Disconnect and remove Pressure Test Gauge

Manifold, Too1- ACL53-3 from Freon tank and

low and high pressure valve service ports. Cap

gauge hoses and service ports, re-place low and

high pressure valve stem protector caps.

1. Install Pressure Test Gauge Manifold, Tool -

ACL53-3 with both gauge valves turned in the

full clockwise position, so that the high

pressure gauge hose is connected to the high

pressure valve service port, and the low

pressure gauge hose is connected to the low

pressure valve service port.

2. Turn low pressure valve located on right front

fender apron,

and high pressure valve located

on condenser, 1-1/2 turns in the clockwise

direction, using

Tool - ACL53-5. Both gauges

will read neutral system pressure.

(Approximately 50 - 75

14.

15.

16.

PUMP-DOWN PROCEDURE