NOTE: If the system pressure is low, or there

is no pressure, this step may be omitted.

5. Loosen the valve fitting on the flexible low

pressure hose, running from the compressor to

the low pressure valve located on right front fender

apron, with Tool-ACL53-7 and al-low refrigerant

to exhaust. When refrigerant is exhausted,

disconnect hose and cap hose and fitting

immediately.

6. Disconnect flexible high pressure hose,

running from the compressor to the high

pressure valve located on the condenser, at the

compressor, using Tool - ACL53-7. Cap

compressor fitting and hose fitting immediately.

9. Remove oil filler cap and oil level indicator.

10. Remove exhaust manifold cross-over pipe and

heater hose clamp attached to lower right

stud on R.H. exhaust manifold.

11. Remove cap screw from compressor which

secures the oil level indicator tube bracket to

the compressor.

12. Remove cap screw from compressor which

secures the compressor to manifold bracket.

13. Loosen compressor head cap screw sufficiently

to remove the bracket supporting the heater

hose and re tighten cap screw. Torque to 20

lbs. ft.

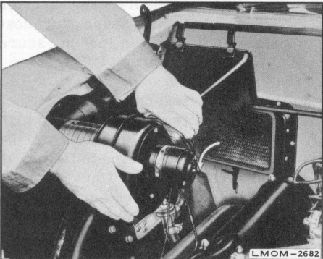

7. Disconnect defroster blower motor bullet

connectors, heater delivery chamber clips, and turn

blower motor clockwise and remove entire

assembly. See figure 19.

Fig. 19. Removing Heater Blower Motor and

Duct Assembly

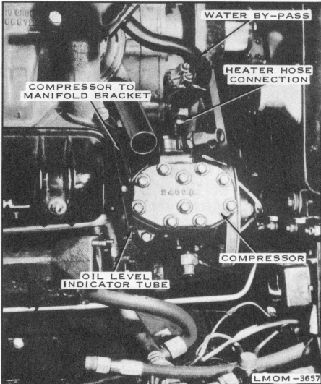

8. Disconnect the water by-pass tube at the water

outlet connection.

14. Disconnect the heater hose connection at the

water pump and move out of way. See figure

20.

Fig. 20. Preparing for Removal of

Compressor

12