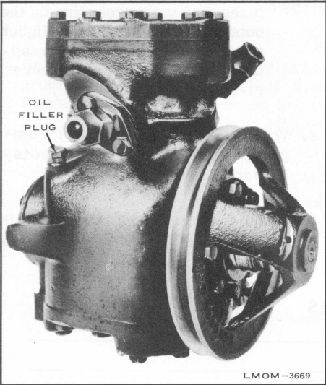

Fig. 33. Compressor Oil Filter

Plug Location

5. Remove blower and motor assembly. NOTE: To

install, reverse the removal procedure.

REMOVAL OF R.H.

MOTOR

1. Remove the two wing nuts securing inspection

cover to evaporator assembly, and remove cover.

2. Disconnect electrical wires at bullet connections.

3. Remove the four screws securing the blower

assembly to the side of evaporator.

4. Remove blower and motor assembly. NOTE: To

install, reverse the removal procedure.

5. Release "Pumped Down" pressure by opening

the shut off valves in the following order. Turn all

valves counterclockwise to open.

1. Open receiver shut off valve.

PRE-DELIVERY

1. Make a visual inspection of all assemblies to

make sure they are tightly mounted. Also check for

2. When no more liquid Freon is flowing past

sight gauge, open low pressure valve.

(a) Oil around connections, indicating a leak.

3. Open high pressure valve. REMOVAL OF

L.H. BLOWER AND MOTOR

ASSEMBLY 1. Disconnect electrical wires at

bullet

connections.

(b) Oil around the compressor head bolts, or

filler plug indicating a leak.

(c) Cracked sight gauge in evaporator

assembly.

2. Remove flexible hose at duct.

(d) Loose compressor drive belt.

3. Remove hex. head screw securing blower

assembly to wheelhouse.

4. Remove three screws securing blower assembly

to package tray.

(e) Disconnected or improperly connected

Bowden wire at modulator. Check for

freedom of movement.

2. Check entire system for leaks.

23