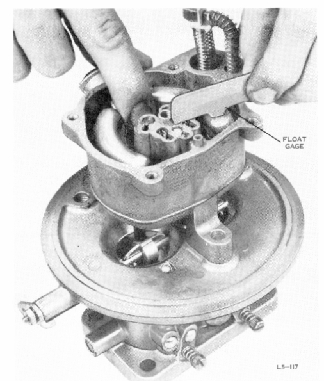

FIGURE 55. CHECKING FLOAT LEVEL

7. Lift the float to completely close

the fuel

inlet valve. Holding the floats in

the closed po

sition, place the float gage across

the float cham

ber, resting one end on the rim of

the float chamber

and the other on the center of the

main body. The

tab on the gauge should just touch

the flat top sur

face of the float at a point on

the flat top surface

farthest from the fuel inlet valve.

Check both

floats in this manner. If one of

the floats is lower

than the other, slightly bend the

portion of the float

lever adjacent to the float to correct

the mis

alignment. A light pressure must

be used, as a

small bend will result in a considerable

change in

the height of the toe of the float.

The float level

can be adjusted by bending the tab

on the float

lever which contacts the fuel inlet

needle. Bend

the tab up to lower the floats,

or down to raise

them. To bend the tab, fit the slot

at the end of the

Snap-On Tool No. MC-140 over the

tab and apply

8. Install the two new idle tubes.

To insure

proper metering, turn the'idle tubes

down tightly

on their seats.

9. Install the new accelerating

pump discharge

needle.

10. Install the two new main well

tubes.

11. Compress the accelerating pump

spring

and washer on the new accelerating

pump piston

and slip the accelerating pump operating

rod

through the slot in the piston stem.

Slip the pump

return spring over the pump operating

rod.

12. Carefully install the pump assembly.

Do

not allow the leather piston to

catch on the edge

of the pump chamber. On the carburetors

having

the type of pump operating rod seal

which fits

around the rod on the top surface

of the throttle

body, slide the spring, washer,

and seal, in that

order, on the pump operating rod,

and install the

snap ring retainer at the lower

end of the rod.

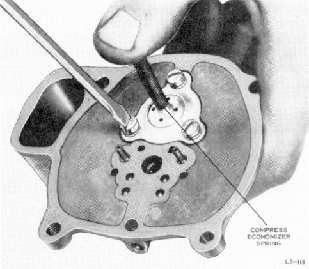

FIGURE 56. INSTALLING ECONOMIZER

DIAPHRAGM

AND STEM ASSEMBLY

13. Place the new economizer diaphragm

assembly on the main body cover

and carefully re

place the economizer clamp, screws,

and lock

washers.

CAUTION

To insure full travel of the economizer

stem, the screws should be tightened

while

the economizer stem is in the compressed

position. (figure 56).

E. Reassembly - Main Body to Throttle

Body

- All Carburetors.

1. Over the accelerating pump operating

rod, place, in this order, the

pump rod seal re

tainer spring, pump rod seal retainer

and pump

rod seal. On earlier models with

a recessed hole

for the pump rod seal, a modification

kit can

be purchased to convert to the

new type of seal.

Fit a new main body to throttle

body gasket on

the protruding foot of the main

body. Place the

main body assembly in position

on the throttle