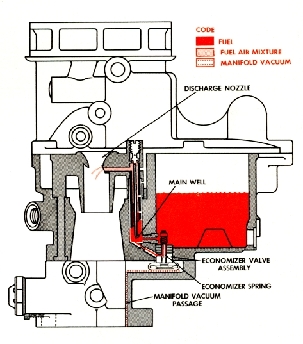

causes fuel to flow through the main

metering

system. The fuel moves up the main

well, passed

main well air bleed where air is added,

the amount

of air increasing proportionally as

the speed in

creases. This mixture of fuel and air,

being

lighter than raw fuel, has a quicker

response to

changes in the venturi pressure, and

also vaporizes

more readily than raw fuel when discharged

into

the venturi air stream. The mixture

of fuel and

air flows through the horizontal channel

and out

the discharge nozzle into the booster

venturi and

then into the air stream in the carburetor

venturi.

The throttle plates control the amount

of fuel air

mixture to the intake manifold, regulating

the

speed and power output of the engine

in accordance

with accelerator pedal movement.

6. POWER ENRICHMENT SYSTEM

During high power operation, the carburetor

must provide a mixture richer than

is needed

when the engine is running at cruising

speed under

no great power requirements. The added

fuel for

power operation is supplied by the

power enrich

ment system, sometimes referred to

as the

economizer system.

This system is controlled by manifold

vacu

um which gives an accurate indication

of the

power demands placed upon the engine.

Manifold

vacuum is strongest at idle and decreases

as the

load on the engine increases. As the

load on the

engine is increased, the throttle

plate must be

opened wider to maintain a given speed.

Manifold

vacuum is thus reduced because the

opened throt

tle plate offers less restriction

to air entering the

intake manifold.

A vacuum passage in the throttle body

trans

mits manifold vacuum to the power

valve diaphragm

in the vacuum chamber. The manifold

vacuum,

acting on the diaphragm at idle or

normal load con

ditions, is strong enough to hold

the diaphragm

down, overcoming the tension of the

power valve

spring on the stem. This holds the

valve closed.

When high power demands place a greater

loadon

the engine and manifold vacuum drops

below a pre

determined point, the power valve

spring over

comes the reduced vacuum and expands,

opening

the

power valve. Fuel from the float

chamber flows

through the valve and out the small

holes in the

sides

of the valve into the passages leading

to both main

wells. A restriction in the passage

leading to each

main well controls the amount of

fuel the power

valve meters, thus insuring an even

distribution of

fuel. In each main well, the fuel

joins the fuel flow in

the main metering system, enriching

the mixture.

As engine power demands are reduced,

mani

fold vacuum increases. The increased

vacuum

acts on the diaphragm, and the diaphragm

over

coming the tension of the power valve

spring,

moves downward. This closes the power

valve

and shuts off the added supply of

fuel which is no

longer required.

POWER ENRICHMENT SYSTEM

7.

SPARK CONTROL VALVE -

MODELS 2110-EE AND 2110-EEC

The spark control valve which is

located in

the throttle body provides an efficient

degree of

spark during periods of acceleration

by momen

tarily providing an intermediate

spark advance

curve between a fully retarded spark

and the

normal spark advance which would

be excessively

retarded when the engine is suddenly

accelerated.

The spark control valve accomplishes

this by

controlling the manifold vacuum admitted

to the

distributor vacuum line which would

bleed off the

higher, venturi vacuum at wide open

throttle.

All manifold vacuum to the distributor

passes

through the spark control valve.

Under normal

road conditions, the spark valve

is held open by a

combination of pressure; atmospheric

outside the

diaphragm, and manifold vacuum from

within. The

combined forces act against the tension

of a preset

factory calibrated spring.

When the manifold