(2) Mechanical - A secondary throttle

shaft lever attached to the primary throttle shaft

opens the secondary plates in relation to prede

termined engine requirements. |

|

|

D. OVER-RUN CONTROL VALVE -Elimin

ates popping back on deceleration. (Not on all

models.) |

|

| |

|

|

|

|

|

|

|

| |

|

E. ANTI-BACKFIRE VALVE - Eliminates

popping back on deceleration. (Not included on

all models.) |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

B. SPARK ADVANCE - |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1) Distributor - Centrifugal - Utilizes

vacuum for initial advance at off idle and centri

fugal force throughout the rest of the engine range. |

|

|

|

|

|

|

|

|

| |

|

F. GOVERNOR - INTERNAL VACUUM

TYPE - Venturi and manifold vacuum acts on a

governor diaphragm to close the throttle plates

when governing speed is reached. |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(2) Distributor - Pressure - Utilizes

changes in air pressure within the carburetor to

control spark timing to satisfy engine speed and

load conditions. |

|

|

|

|

|

|

|

|

| |

|

G. GOVERNOR - EXTERNAL VACUUM

TYPE - Uses an external source of vacuum

acting on the governor diaphragm when governing

speed is reached. |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C. VACUUM OPERATED AUTOMATIC

TRANSMISSION -Uses manifold vacuum to control

the shift points in the transmission. |

|

|

H. GOVERNOR - MECHANICAL - A separate

governor controls the throttle plates of the car

buretor. |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

OPERATION |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1. PRIMARY SYSTEM |

|

|

|

|

|

|

|

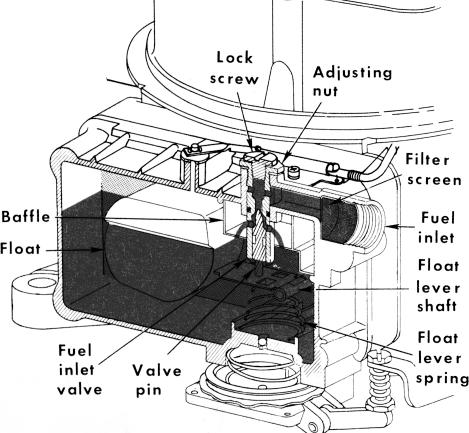

which rises and falls with the fuel level. As the

fuel level drops, the float drops, opening the needle

valve to allow fuel to enter the float chamber.

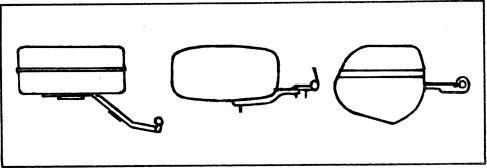

There have been three different shape floats used

in these carburetors. These floats are NOT

interchangeable. |

| |

|

|

|

|

|

|

|

|

|

|

A. FUEL INLET SYSTEM - The fuel enters

the fuel bowl thru a filter screen and into the fuel

inlet valve which is frequently referred to as the

fuel inlet needle and seat assembly. The amount

of fuel entering the fuel bowl is determined by the

space between the top of the moveable needle and

its seat and also by the pressure from the fuel

pump. Movement of the needle in relation to the

seat is controlled by the float and lever assembly |

|

|

| |

|

|

|

|

|

|

|

| |

|

|

When the fuel reaches a specified level, the

float moves the needle valve to a position in its

seat where it restricts the flow of fuel, admitting

only enough to replace that being used. Any slight

change in the fuel level causes a corresponding

movement of the float, opening or closing the fuel

inlet needle valve to immediately restore or hold

the correct fuel level. THE FUEL INLET SYSTEM

MUST CONSTANTLY MAINTAIN THE SPECIFIED

LEVEL OF FUEL AS ALL THE OTHER METER

ING SYSTEMS ARE CALIBRATED TO DELIVER

THE PROPER MIXTURE ONLY WHEN THE FUEL

IS AT THIS LEVEL. |

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

Three different types needle and seat are used

in these model carburetors. |

| |

|

|

|

|

|

|

|

|

| |

|

|

|

A float spring is incorporated under the float,

in some applications, to assist in keeping the float |

| |

|

|

|

|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

Primary Fuel Inlet System |

|

|

|

|

|

|

|

Three Types of Floats |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

2- |

|

|

|

|

|

|