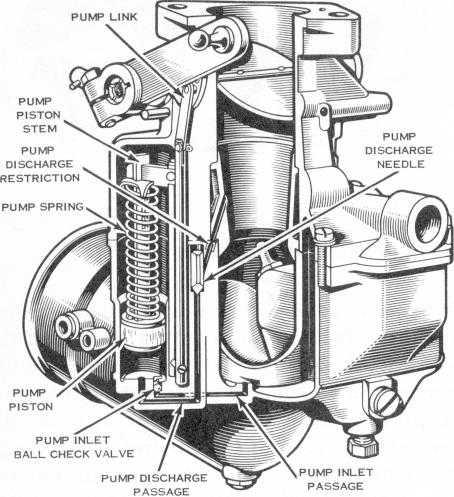

passages can gain speed and maintain the desired balance of fuel and air. The accelerating pump system operates during this interval, supplying fuel until the other systems can provide the proper mixture. When the throttle is closed, fuel enters the pump well through a passage from the float chamber. The pump inlet ball check valve permits fuel to enter the pump well but prevents a reverse flow of fuel when the

charge needle valve closes the passage when the pump is not discharging fuel. In addition to preventing fuel from being drawn from the pump well by the suction of the airstream in the venturi at high speeds, the needle valve seals the passage so that air will not be drawn into the system when the throttle is again closed and the pump piston is raised to draw in another charge of fuel.

pump is operated. The pump rod, which is linked to the throttle lever, moves downward as the throttle is opened. The horizontal arm at the top of the pump rod slides down in the slot in the pump piston stem, compressing the pump spring. The spring presses the pump piston down, forcing fuel through the passage to the pump discharge needle valve. The spring overriding feature provides a sufficiently long interval of discharge, regardless of how suddenly the throttle is opened. The fuel, under pressure from the pump piston, unseats the pump discharge needle valve and flows past it to the pump discharge restriction where the flow is metered. It is then sprayed into the airstream in the venturi. The pump dis

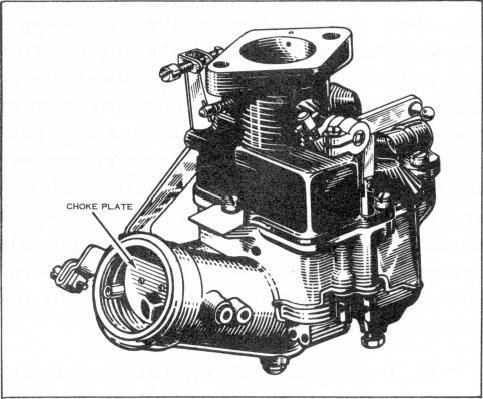

6. CHOKE SYSTEM

When starting a cold engine, much of the vaporized fuel from the carburetor condenses to a liquid upon contact with the cold surfaces of the intake manifold. This results in hard starting, loss of power, and stalling. Closing the choke plate in the carburetor airhorn confines manifold vacuum within the carburetor, thus drawing a rich flow of fuel from the idle and main

metering systems. When the engine starts, enough air is drawn through the springloaded poppet valve in the choke plate to prevent flooding. A throttle kicker lever and cam mechanism increases the throttle opening at idle during choking, giving a faster idle rpm to prevent stalling. After the engine has warmed up, the temperature of the intake manifold will be high enough to prevent condensation of the normal fuel discharge and choking will no longer be necessary.