| |

|

|

|

|

|

|

|

9D-3

MODELS 2G-2GC-2GV

PAGE 13

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

As the engine warms up, hot air from the exhaust manifold is drawn into the thermostatic coil housing. The hot air causes the coil to slowly relax its tension. Thus the choke valve is allowed to move gradually to the full open position.

|

|

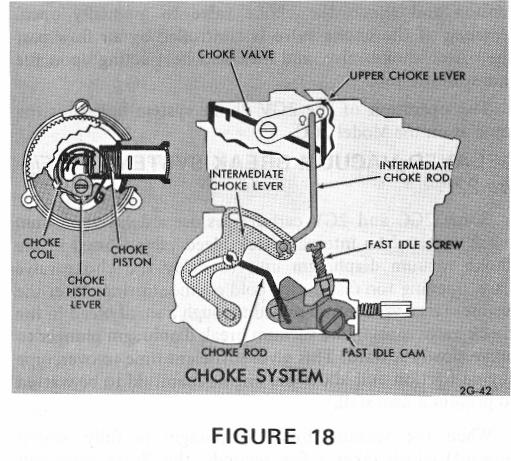

The split linkage choke is designed to let the choke valve and fast idle cam work independently. The operation of the choke coil and piston is the same as used on the conventional system. The split linkage operates in the following manner:

|

During the warm-up period the choke piston also serves to modify the choke action to compensate for varying engine loads on acceleration. Any acceleration or increased load decreases the vacuum pull on the choke piston. This allows the thermostatic coil to momentarily increase choke valve closure to provide the engine with a richer mixture for acceleration.

|

|

The intermediate choke rod is attached to a slot near the outer end of the intermediate choke lever, while the choke rod is attached to a slot approximately half way out on the lever. The result is, that as the thermostatic coil warms up and the intermediate choke lever rotates clockwise, the intermediate choke rod moves farther than the choke rod; this allows the choke valve to open fully while still maintaining a fast idle. This design provides a relatively short choking period with adequate fast idle for a cold engine.

|

To prevent stalling during the warm-up period it is necessary to run the engine at a slightly higher idle speed than for a warmer engine. This is accomplished by a screw which rests on the steps of the fast idle cam. The fast idle cam is linked to the choke valve shaft by the choke rod, choke trip lever and upper choke lever and collar assembly. The rotation of the fast idle cam in relation to the choke valve holds the throttle valves open sufficiently during the warm-up period to increase the idle RPM until the choke valve moves to the full open position.

|

|

| |

HOT WATER CHOKE SYSTEM (Fig. 19)

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

When the automatic choke is in operation the driver may wish to advance the throttle to the full, wide open position. Since this would decrease pull upon the choke piston, thereby closing the choke valve, it is necessary to provide increased carburetor air flow by opening the choke valve mechanically. To accomplish this, a tang on the fast idle cam is made to contact the throttle lever at wide open throttle position to sufficiently open the choke valve. This is called a choke unloader and also serves to de-choke a flooded engine during starting, whenever the engine is cranked with the accelerator held fully depressed.

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

FIGURE 19

|

|

|

|

| |

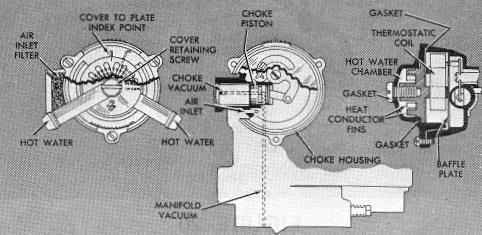

The hot water choke system differs from the conventional choke system in the following manner:

|

| |

Instead of using hot air from the exhaust manifold to heat the thermostatic coil, heat from the engine hot water is used. The engine water is circulated directly from the engine to a chamber in the choke cover. The hot water choke has an inner and outer cover. The inner cover retains the choke coil and the outer cover provides the chamber through which the hot water is circulated. Pick up fingers on the inner cover extend into the hot water chamber and pick up heat from the water. The heat is then transmitted to the inner cover and around the thermostatic coil. The choke housing inside baffle plate is made of insulating material to hold the heat around the thermostatic coil which will gradually relax the tension on the coil and allow the choke valve to open.

|

SPLIT LINKAGE CHOKE - MODEL 2GC (Fig. 18)

|

|

|

|

| |

|

|

|

|

|

| |

The conventional choke piston is used to control the vacuum break and to assist in opening the choke valve as the coil relaxes its tension. Air flow needed to control vacuum acting on the choke piston enters the choke housing through an opening at the side of the housing which is covered with a polyurethane filter. The piston and housing are designed so that when the choke valve is in the wide open position, the choke piston blocks off the vacuum passage in the housing. This allows very little or no air flow through the inner choke housing when the choke is open.

|