| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

9D-3

MODELS 2G-2GC-2GV

PAGE 25

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASSEMBLY OF AIR HORN (Fig. 41)

|

|

|

|

|

11. Lightly lubricate shaft of accelerator pump outer lever, if removed, with lubriplate before installation. Install plastic washer, if used, over pump shaft so that when the pump shaft is inserted into the air horn, the plastic washer is between the lever and air horn casting. Position accelerator pump outer lever partially through air horn and align flats on pump inner lever and outer lever shaft. Install and secure levers with retaining screw, tightening securely.

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

CAUTION: Do not bend retaining ear on inner

|

|

| |

|

|

|

lever which holds the pump plunger assembly

|

|

| |

|

|

|

into the lever as throttle sticking can result.

|

|

|

|

| |

|

12. On 2GV models using the vacuum-operated vent valve, install vent valve assembly diaphragm spring into air horn cavity; then install vent valve assembly and diaphragm by carefully pushing downward until seated. Install (4) attaching screws and tighten securely.

|

| |

|

|

|

|

|

|

|

13. Except Vega models, install power piston assembly into power piston bore. Stake power piston retainer lightly in place. Power piston should travel up and down freely after installation.

|

| |

|

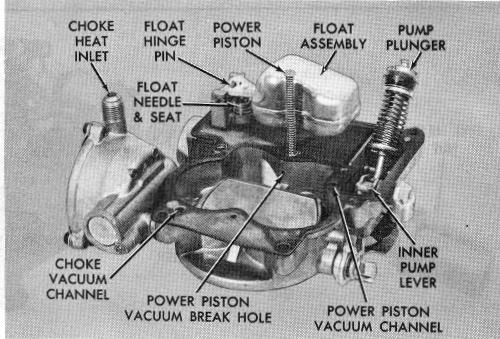

FIGURE 41

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

3. On early 2GC units where the choke piston and lever assembly is riveted to the choke shaft, install choke piston on choke lever and link with piston pin; flat side on choke piston faces inward toward air horn. Install choke shaft into air horn and rotate shaft to install choke piston in choke housing. Install choke valve, upper choke lever, trip lever and align as decribed in steps 6 and 9.

|

|

14. Install float needle seat gasket into casting, then install needle seat and tighten securely with tool BT-3006 or, if unavailable, a wide blade screwdriver.

|

| |

|

15. If removed, install metal needle seat baffle to float retainer legs in air horn - notch in baffle goes toward accelerator pump.

|

| |

|

16. Install new air horn to float bowl gasket making sure gasket is indexed with locating dowel.

|

| |

4. On late 2GC units, and 2GV models, the choke trip lever is staked on to choke shaft. Install upper choke lever and choke rod on choke shaft. Tang on choke lever should face towards trip lever and be positioned above trip lever.

|

|

17. Install float needle into needle seat and align float assembly with legs in air horn; then, install retainer pin through metal baffle (if used) and float assembly. On models using a float needle pull clip, make sure pull clip is aligned properly in float arm.

|

| |

5. Slide choke shaft assembly through choke shaft bores in air horn.

|

|

|

|

NOTE: If a nitrophyl (plastic) float is used,

|

|

| |

|

|

|

position cutout in float assembly toward power

|

|

| |

6. Install choke valve into slot in choke shaft - "RP" or "C" trademark should be facing upward with choke closed. Install (2) choke valve retaining screws. Do not tighten.

|

|

|

|

piston when installing float.

|

|

|

|

|

|

|

| |

|

|

Check float assembly for free operation.

|

|

|

|

|

| |

|

18. Carefully adjust float level and drop following procedures and specifications listed in the "D" Section of the Delco Carburetor Parts and Service Manual (9X). Drop tang on rear of float arm should point downward toward air horn.

|

| |

7. Install choke piston on choke piston lever and link assembly with piston pin. If choke piston has a flat on one side, this should face inward, toward choke valve.

|

|

| |

8. Install choke piston lever and link assembly into choke housing. Align flats on piston lever with flats on choke shaft. Install retaining screw in end of choke shaft. Tighten securely.

|

|

|

|

NOTE: Make sure the float is properly aligned

|

|

| |

|

|

|

on the air horn. If it is necessary to bend the

|

|

| |

|

|

|

float arm for alignment, recheck the float level

|

|

| |

|

|

|

setting.

|

|

|

|

|

|

|

|

| |

9. To center choke valve and shaft, close choke valve, then place .020" feeler gauge between choke trip lever and upper choke lever. Center shaft to maintain above clearance, then tighten choke valve screws and stake securely. (On 2G models, connect torsion spring to idle cam lever.) Choke valve should move freely in air horn bore.

|

|

19. Carefully place air horn assembly on float bowl, making certain the pump plunger is properly positioned in the pump well. Lower the air horn gently, straight down, then install (8) air horn to float bowl attaching screws and lockwashers, if used. Tighten securely following sequence in Figure 42, page 26.

|

| |

|

|

|

|

NOTE: Longer air horn screw (#1) goes in top of pump housing. The choke cable retaining bracket (2G manual choke models) is retained by number 7 and 8 screws.

|

|

|

| |

10. Install accelerator pump plunger and rod to pump inner lever - end of plunger rod faces inward. Install retaining clip, if used, on pump rod end crimping ends of "C" clip for clip retention.

|

|

|

|

|

|

|