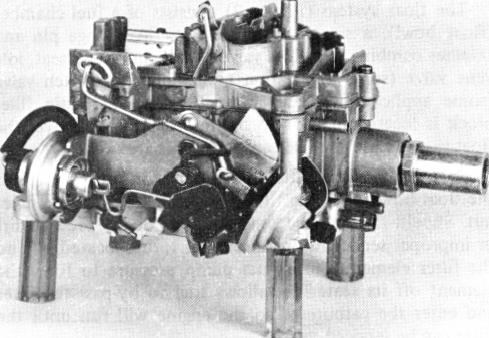

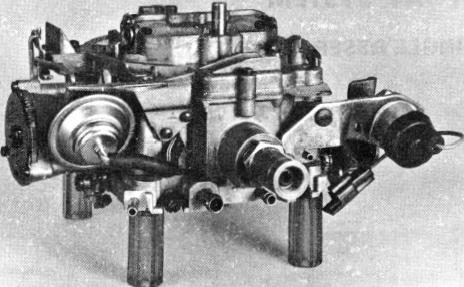

TYPICAL MODELS 4MV-4MC

GENERAL DESCRIPTION

There are three separate basic carburetor models. They are designated as 4M, 4MC, and 4MV. The 4M is the basic carburetor equipped for manual choke operation. The 4MC model is an automatic choke carburetor with the choke housing and coil mounted at the side of the float bowl. The 4MV is an automatic choke model designed for use with a manifold mounted thermostatic choke coil. Except for choke systems, all models have basically the same principles of operation.

The Quadrajet is a four-barrel, two-stage carburetor of down-draft design. Its simplicity in construction makes it easy to service, yet its versatility and principles of operation make it adaptable from small to very large engines, without major casting changes.

The Quadrajet carburetor has two stages in operation. The primary (fuel inlet) side has small 1-3/8" bores with a triple venturi set-up equipped with plain tube nozzles. Operation is similar to most carburetors using the venturi principle. The triple venturi stack up, plus the small primary bores, result in more stable and finer fuel control during idle and part throttle operation. During off-idle and part throttle operation, fuel metering is accomplished with tapered metering rods, operating in specially designed jets positioned by a manifold vacuum responsive piston.

The secondary side of the Quadrajet has two large (2-1/4") bores. These, added to the primary, give enough air capacity to meet most engine requirements. The air valve is used in the secondary side for metering control and supplements the primary bores to meet air and fuel mixture requirements of the engine.

The secondary air valve mechanically operates tapered metering rods which move in orifice plates, thereby

controlling fuel flow from the secondary nozzles in direct proportion to air flowing through the secondary bores.

The float bowl is centrally located to avoid problems of fuel spillage causing engine turn cutout and delayed fuel flow to the carburetor bores. The float bowl reservoir is small in design to reduce fuel evaporation loss during engine "shutdown" hot.

The float system has a single pontoon float and fuel valve for simplification and ease in servicing. An integral fuel filter, if used, located in the float bowl ahead of the float needle valve, is easily removed for cleaning or replacement.

The throttle body is aluminum to reduce overall weight and improve heat conduction to prevent icing. A heat insulator gasket is used between the throttle body and bowl to prevent fuel percolation in the float bowl.

Early Quadrajet applications use a shim between the throttle body and flange gasket. The shim is used to protect the carburetor aluminum throttle body from exhaust gases flowing through the heat cross-over passage in the intake manifold.

SERVICE FEATURES

The primary side of the carburetor has six operating systems. They are float, idle, main metering, power, pump and choke. The secondary side has one main metering system plus accelerating wells on some models. All metering systems receive fuel from the one float chamber.

The following text covers the operating systems for ease in trouble-shooting and also recommended service procedures. There are some design variations between different