MODELS 4M-4MC-4MV PAGE 4

models which will be covered in that part of the text pertaining to the particular system or service procedure.

OPERATING SYSTEMS FLOAT SYSTEM

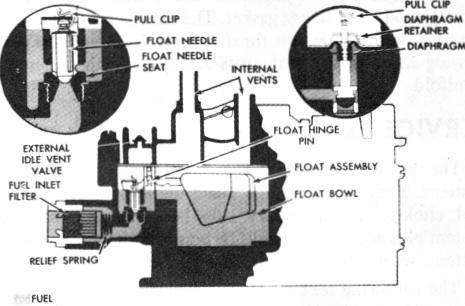

SINGLE RESERVOIR (Fig. 1)

FIGURE 1

The Quadrajet carburetor is unique in that it has a centrally located fuel reservoir (float bowl). The float bowl is centered between the primary bores and is adjacent to the secondary bores. This type design assures an adequate fuel supply to all carburetor bores, resulting in excellent performance with respect to car inclination or severity of turns.

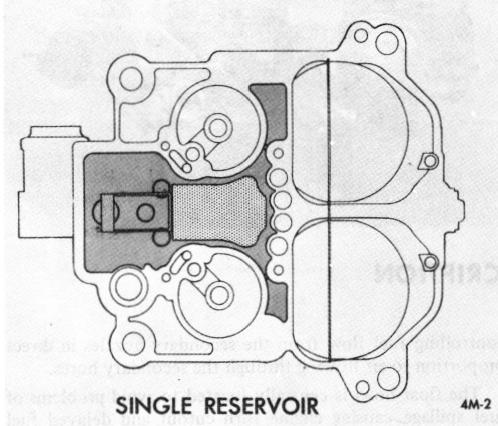

FLOAT SYSTEM (Fig. 2)

The float pontoon is solid and is made of a light, closed-cell plastic material. This feature gives added bony-' ancy which allows the use of a single float to maintain constant fuel levels.

The float system (Figure 2) consists of a fuel chamber (float bowl), a single pontoon float, float hinge pin and retainer combination, float valve - pull clip - and seat, idle vent valve (some applications), vacuum vent switch valve (some applications), and internal vents. A plastic filler block is located in the top of the float chamber over the float valve to prevent fuel slosh into this area.

On most models, a fuel inlet filter is an integral part of the float bowl, with the filter located behind the fuel inlet nut. Should the filter become plugged due to excessive dirt or improper service, a pressure relief spring located behind the filter element allows fuel pump pressure to force the element off its seat. This allows fuel to by-pass the filter and enter the carburetor so the engine will run until the filter can be serviced.

It is very important that the filter be serviced periodically to prevent dirt from entering the carburetor metering orifices.

The float system operates in the following manner:

Fuel from the engine fuel pump enters the carburetor fuel inlet passage. It passes through the filter element, fuel inlet valve, and on into the float bowl chamber. As the incoming fuel fills the float bowl to the prescribed level, the float pontoon rises and forces the fuel inlet valve closed, shutting off fuel flow. As fuel is used from the float bowl, the float drops allowing the float valve to open, allowing more fuel to again fill the bowl. This cycle continues, maintaining a constant fuel level in the float bowl.

A float needle pull clip, fastened to the float needle valve, hooks over the edge of the float arm at the center as shown in Figure 2. Its purpose is to assist in lifting the float valve off its seat whenever fuel level in the float bowl is low.

CAUTION: Do not place pull clip through small holes in top of float arm. Severe flooding will result.

There are two types of float needle valves used in the Quadrajet carburetor: One type is diaphragm assisted and the other is the conventional needle and brass seat.

The diaphragm assisted float needle (shown in the right inset Figure 2) is used primarily with a smaller float and on engines equipped with high pressure fuel pumps. The needle seat is a brass insert and is pressed into the bowl fuel inlet channel below the diaphragm needle tip. The seat is not removable, as the needle valve tip is of a material which makes seat wear negligible. Care should be used during servicing so that the seat is not nicked, scored, or moved. The float valve is factory staked and tested and should not be re-staked in the field.

FIGURE 2