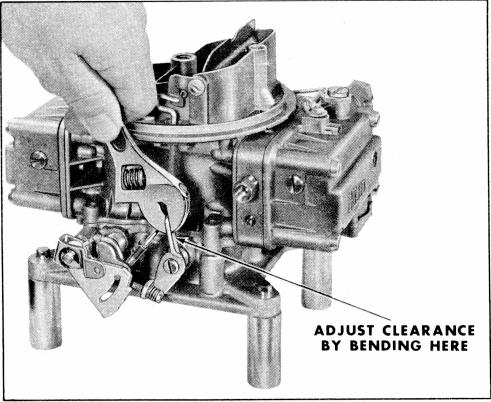

(1) Applies only on model 4160 with

mechanical secondarys. Check the choke unloader

adjustment. Hold the choke plate closed and the

throttle fully open. The correct clearance from the

choke plate to the back of the main body must be

a minimum of 3/16. |

|

|

(4) After the engine reaches its normal

operating temperature, adjust the idle speed screw

to idle the engine at the specified rpm. |

| |

|

|

|

|

|

|

| |

|

(5) First set one of the two idle adjusting

needles for the highest steady manifold vacuum

reading. If a vacuum gage is not available, obtain

the smoothest running, maximum idle speed by

turning the idle adjusting needle in until the rpm

begines to drop off, then backing the needle off

over the "high spot" until the rpm again drops

off. Set the idle adjusting needle halfway between

these two points for a satisfactory idle mixture

setting. Then repeat the procedure with the other

needle. Should these adjustments show an increase

in idle rpm, reset the idle speed screw to obtain

the specified idle rpm and adjust the idle adjusting

needles again. |

| |

|

|

|

|

|

|

|

|

|

See Figure 41 for the correct method

for correcting this clearance. |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| |

|

C. ADJUSTING THE DASHPOT - The dash

pot, on carburetors for engines equipped with

automatic transmissions, are to be adjusted after

idle speed and mixture settings have been com

pleted. Loosen the dashpot screw and turn the

complete dashpot in the direction desired. Check

the Holley Catalog Sheets for the clearance

between the dashpot and primary throttle lever. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Figure 41. Correcting Choke Plate Clearance |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

D. ADJUSTING THE AUTOMATIC CHOKE |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

3. ADJUSTMENTS ON THE VEHICLE |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

(1) The automatic choke is accurately set

at the factory to give the best possible all weather

operation. To return the choke to the original

setting, line up the index mark with proper speci

fication. |

| |

A. ADJUSTING FAST IDLE SCREW- The

fast idle cam screw should just touch the lowest

step of the fast idle cam, at curb idle. This

adjustment should be made before adjusting the

idle adjusting needles. |

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

(2) If for some reason a richer or leaner

mixture during the warm-up period is desired, it

can be obtained by rotating the thermostat cover.

Never set the index mark on the cover more than

two graduations off the specified settings. |

| |

|

B. ADJUSTING THE IDLE |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

(1) Adjustments, to be precise and ac

curate, must be made when the vehicle is on level

ground. |

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

E. EXTERNAL FUEL LEVEL ADJUST

MENT - For models with external fuel level

adjustment. |

| |

(2) Seat the idle adjusting needles lightly

and back each off a full turn if there is any

doubt about this not having been done during

reassembly. |

|

|

| |

|

|

|

|

|

|

| |

|

|

(1) Check the fuel pump pressure before

altering the fuel level. |

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

NOTE |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

(2) With the air cleaner removed andthe

ignition "off", remove the sight plug (Figure 42)

and then remove the bowl lower attaching screw

farthest from the fuel inlet (Figure 43). |

| |

|

Care must be taken when seating the idle

adjusting needle not to turn the screw

tight against the seat, grooving the tip of

the needle. If the needle becomes grooved,

a smooth idle cannot be obtained. |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

(3) Drain off the gasoline in a shallow

pan using extreme care not to spill gasoline and

create a fire hazard. |

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

(3) Start the engine and allow the opera

ting temperature to reach normal. |

|

|

|

|

|

|

| |

|

|

|

|

(4) Re-install the fuel bowl screw. |

|