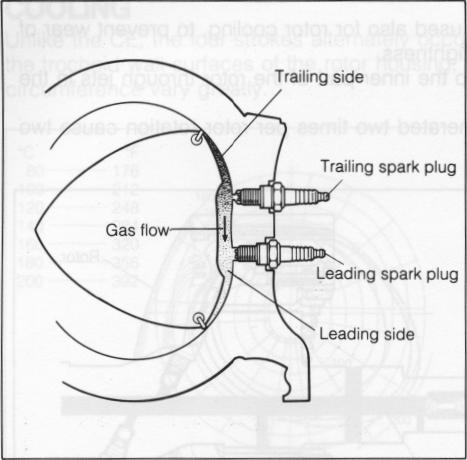

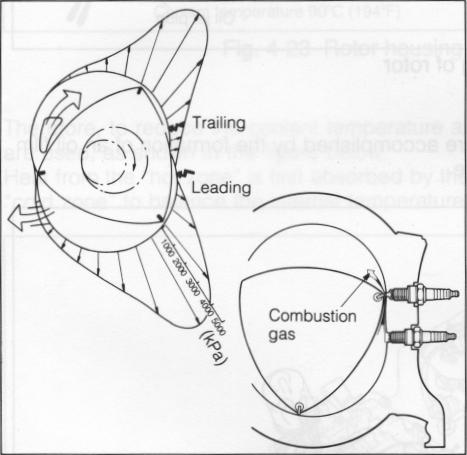

Fig. 4-19 Adjacent chamber pressure difference

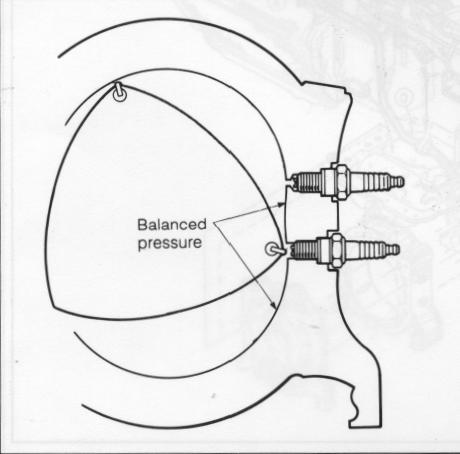

Fig. 4-20 Adjacent chamber pressure balance

2-SPARK PLUGS

For the RE, the working chambers are constantly moving in the direction of rotation. As a result, at the vicinity of top dead center of the compression stroke, the compression pressure at the trailing side is higher than the compression pressure at the leading side, with the result that the compressed air/fuel mixture is forced in to the leading side. Thus, as the trailing spark plug ignites, combustion efficiency is improved.

However, when the apex seal passes by the trailing spark plug hole immediately after ignition, the difference between the combustion pressure and the lower compression force in the following working chamber causes the exhaust gas to leak past the spark plug hole and flow in the direction of lower pressure.

To prevent this leakage, the trailing spark plug hole is made smaller.

(This can cause fouling of the trailing spark plug at low rpm but, due to the self-cleaning effect of the plug, it is cleaned as the engine runs at higher rpm.)

As there is no difference of pressure within the succeeding working chamber (no difference between combustion force and compression force), a leading spark plug is provided where the exhaust gas does not flow in and the hole can be larger, thus improving low-speed stability and starting performance because the spark plug does not get fouled comparatively. The two spark plugs are ignited by their respective ignition coils (leading and trailing).

15