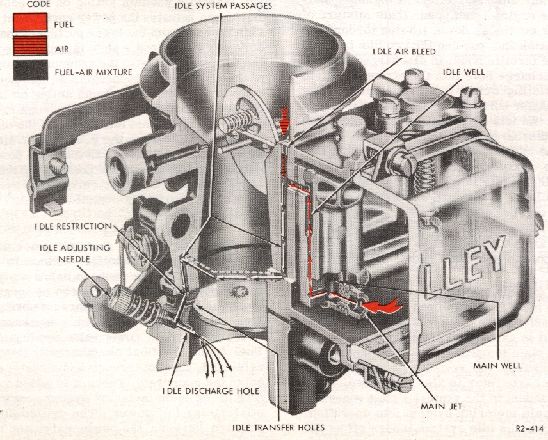

3. MAIN METERING SYSTEM

When the engine is running, the intake stroke of each

piston draws air through the carburetor. As this air

passes through the venturi of the carburetor, the drop

in pressure in the venturi creates what is commonly

called a vacuum. The strength of that vacuum varies in

proportion to the velocity of the air flow through the

venturi. This, in turn, is governed by the speed and

power output of the engine.

At normal cruising speeds, the difference between the

normal, atmospheric air pressure in the float chamber

and the vacuum in the venturi is used to operate the

main metering system. This pressure differential draws

a metered flow of fuel from the float chamber through

the main metering system and out the main nozzle into

the air stream in the venturi. When the fuel passes out

of the float chamber, it is metered (or measured) by the

main jet as it flows into the bottom of the main well.

The fuel moves up the main well past the two

narrow air bleed passages and enters the main nozzle.

Filtered air from the carburetor air inlet enters the air

speed bleed and passing out the two narrow air

bleed passages is mixed with the fuel flow in the

main well. The high speed bleed meters a properly

increasing amount of air into the fuel as speeds

increase, stabilizing the fuel discharge and main-

taining the required mixture ratios. This emulsion of

fuel and air, being lighter than the raw fuel, has a

more instantaneous response to any change in

venturi vacuum and is more readily vaporized than

raw fuel upon being discharged into the air stream.

The fuel flows through the main nozzle and is

sprayed onto the open choke plate in the venturi.

Airstream turbulence over the distribution pin and

choke plate distributes the fuel over the lower

portion of the choke plate where it is vaporized and

mixed with the air flowing through the carburetor.

The throttle plate controls the amount of fuel-air

mixture admitted to the intake manifold, regulating

the engine speed and power output in accordance

with accelerator pedal movement. The distribution

pin extending perpendicularly from both sides of the

choke plate creates a turbulence as an aid to the

proper distribution of the mixture to all cylinders of

IDLE SYSTEM