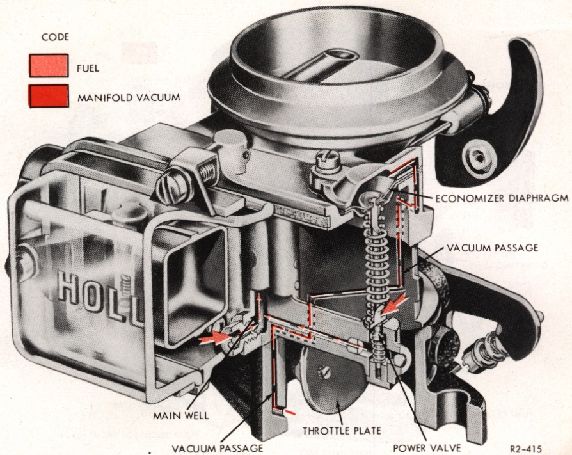

POWER ENRICHMENT SYSTEM

6. ACCELERATING PUMP SYSTEM

The air flowing through the carburetor responds almost

immediately to any increase in throttle opening. There is,

however, a brief interval before the relatively heavier fuel-air

mixture in the narrow carburetor passages can gain speed and

maintain the desired balance of fuel and air. The accelerating

pump system operates during this interval, supplying fuel until

the other systems can provide the proper mixture.

When the throttle is closed, the pump return spring forces the

pump diaphragm toward the back of the pump chamber,

drawing fuel into the chamber through the pump inlet. The

pump inlet contains a ball check valve which opens to admit

fuel from the float chamber into the pump chamber, and closes

when the pump is operated to prevent a reverse flow of fuel.

When the throttle is opened, the movement is transmitted by

the pump link to the pump operating lever. That lever presses

the pump rod sleeve inward, compressing the pump spring.

The pump spring, in turn, presses on the diaphragm, forcing

the fuel from the pump chamber into the pump discharge

passage. The "overriding" feature

provided by the pump spring assures an even, prolonged

discharge of fuel regardless of how suddenly the throttle

is opened and cushions the action of the pump to prevent

damage to the pump linkage due to those sudden throttle

movements.

The fuel, under pressure from the diaphragm, flows

through the pump discharge passage and, forcing the

pump discharge ball check valve and weight up, passes

into the pump discharge nozzle screw. The pump

discharge ball check valve seals the passage when the

pump is not discharging fuel. The hexagonal weight holds

the ball check valve on its seat to prevent a loss of fuel

from the pump chamber due to the siphoning effect of the

airstream at high engine speeds.

Flowing up the hollow pump discharge nozzle screw, the

fuel passes out holes in the head of the screw into the

pump discharge nozzle and is sprayed into the airstream

in the venturi. A slot cut into the pump discharge nozzle

vents the system to prevent the pump discharge ball check

valve and weight from being lifted and fuel drawn from

the pump chamber by the siphoning tendencies of the

airstream at high engine speeds.