2. SPECIAL TOOLS AND IMPROVISED TOOLS

This carburetor may be overhauled using ordinary tools if a reasonable amount of care is exercised. Overhaul will

be facilitated, however, and damage to parts avoided if factory-approved tools are used. The special tools

recommended for use in the overhaul of this carburetor are listed below.

TOOL

SNAP-ON

TOOL NO.

HOLLEY

TOOL

Main Jet Wrench

TMC-36

82R-49

Power Valve Wrench

MC-128

82R-34

(Used for fuel inlet seat retainer screw)

Float Gauge

MC-164

82R-53

ng the distribution pin may be

-tip punch having an end diameter

vised

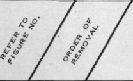

PART NAME

2

1

Pump Link Cotter Pin

3

2

Throttle Body Screws and

Lockwashers (2)

3

Throttle Body Gasket

3. MASTER REPAIR KITS

placements

assembly procedure

l parts for which

4. DISASSEMBLY

A. PREPARATION

During disassembly, use separate containers for the

component parts of both major subassemblies; the

main body assembly, and the throttle body assembly.

Cleaning, inspection, and reassembly will be

facilitated by use of separate containers.

-MAIN BODY ASSEMBLY

FROM THROTTLE BODY ASSEMBLY

The following list contains all parts removed in

separating the main body assembly from the throttle

body assembly.

Parts to be discarded

and replaced from a Master Repair Kit are marked

with an asterisk (*).

Figure I. Disassembly - Two Maior Subassemblies

-10-