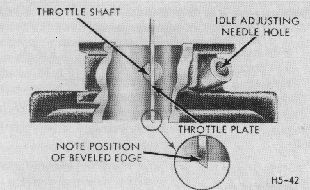

Figure 32. Installing Throttle Plate

of the throttle plate and the throttle bore, and if the

throttle plate moves freely throughout its range of

travel, throttle plate alignment is satisfactory. Hold

the throttle plate in the closed position and tighten the

throttle plate screws.

(2)

Install the new pump link in the throttle lever

with the double bend of the link uppermost. Secure

the pump link in place with one of the new pump link

cotter pins. (The two holes in the throttle permit

adjustments to compensate for climatic conditions;

place the pump link in the hole nearest the throttle

shaft for normal climatic conditions, or use the outer

hole for continuous extreme cold weather operation.)

(3) Install the new idle adjusting needle with its

spring. Turn the needle down gently with the fingers

until it seats, then back it off one full turn. Take care

not to force the needle down on its seat. This will

groove the tip of the needle and make it impossible to

accurately adjust the idle mixture.

(4) On carburetor for automatic transmission

engines, install the dashpot lever, spring, and screw.

B. REASSEMBLY-MAIN BODY

(1)

Place a new gasket on both sides of the pump

discharge nozzle, then insert the pump discharge

nozzle screw into the channeled side of the nozzle.

(The pump discharge nozzle screw may be identified

by the hole drilled vertically from its tip to a point

shortly below the head of the screw, where it joins a

short horizontal drilled passage terminating in a

groove in the side of the screw.) Install the pump

discharge nozzle in the recess at the top of the venturi

in the main body. Allow the pump discharge nozzle to

rotate to the limits of its travel in a clockwise direction

as the nozzle screw is tightened. The nozzle will stop

against the edge of its recess in its proper operating

position after a small amount of rotation.

NOTE

In the List No. 763 and 831 Carburetors,

however, the pump discharge nozzle should

be held in a counter-clockwise position

against the limits of its rotational travel as the

nozzle screw is tightened.

(2)

Position the choke bracket on the boss on the

main body. Slide the choke shaft and lever assembly

into the main body and secure it in place by driving

the choke shaft retainer pin into the small vertical hole

in the top of the choke shaft boss.

(3)

Rotate the choke lever until the choke

lever swivel is below the choke shaft. Insert the

choke plate into the slot in choke shaft with the stem

and spring of the poppet valve extending upward.

CAUTION

Take care not to damage the tip of the main

nozzle while installing the choke plate.

(4)

Center the choke plate to avoid damaging

the venturi then close the choke plate by rotating the

choke lever in a counter-clockwise direction. Install

the choke plate screws, fitting the screw with the

attached lockwasher in the hole nearest the choke

lever. Turn the screws down snugly but not tightly.

Rotate the choke lever until the choke plate is nearly

inverted and the poppet valve stem and spring extend

downward. Align the distribution pin hole in the

choke shaft with the corresponding hole in the choke

plate. Brace the choke shaft from beneath and drive

the distribution pin into position. Install the

distribution pin so the clearance between

.

the tip of

the pin and the venturi wall is equal on both sides

NOTE

The List No. 763 and 831 Carburetors use a

hex-head screw on the side of the choke shaft

nearest the fuel bowl and pump discharge

nozzle. A stem extends above the hex-head

of the screw to facilitate proper fuel

distribution in C.O.E. installations. A

shakeproof external tooth lockwasher is used

to retain the screw. The regular choke plate

screw continues in use as the other plate

screw.