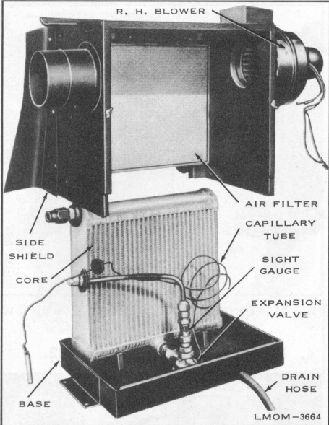

Fig. 28. Evaporator Assembly

5. Roll back rubber shield on low pressure tube

and clip capillary tube in place.

6. Replace flexible duct from L. H. blower to

evaporator.

7. Connect blower wires according to wire colors.

8. If system has been pumped down, open shut off

valves in the following order, with Tool -

ACL53-5. (Turn all valves in the full

counterclockwise direction):

1. Receiver shut off valve.

2. When no more liquid Freon is flowing past

sight gauge, open low pressure valve.

3. Open high pressure valve.

11. To assemble evaporator, reverse removal

procedure. Use new seal when connecting

short section of high pressure hose to sight

gauge.

9.

If system has been exhausted, pres-sure check,

evacuate and charge according to procedure

under "Pres-sure Testing, Evacuating and

Charging System".

10. Replace spare wheel and tire.

1. Position evaporator assembly, with R. H. blower

assembly attached, in the luggage

compartment.

11. Replace rear seat speaker.

2.

3. Remove caps on high pressure tube and fitting on

left side of evaporator assembly. Install new

seal and tighten fitting with Tool - ACL53-6.

Replace four hex head attaching screws

securing evaporator to floor pan and tighten.

The air drawn into the evaporator unit by the

blowers, must first pass through an air filter. This filter

is a permanent type which may be washed in clear

cold water and reused. In washing make sure water

passes through filter in the opposite direction to

normal air flow only. See figure 29.

4. Connect low pressure tube to evaporator fitting

and tighten with Tool - ACL53-7.

In normal operation, the air passing through the filter

in the direction indicated,

causes electrostatic pick up

of

21

INSTALLATION OF EVAPORATOR

ASSEMBLY

REMOVING AIR FILTER